PLATE LOAD TESTING

Plate load testing is performed on a prepared ground surface and is a method for determining the strength characteristics of soil in situ by measuring the amount of deformation and force when a rigid plate is forced to penetrate the soil.

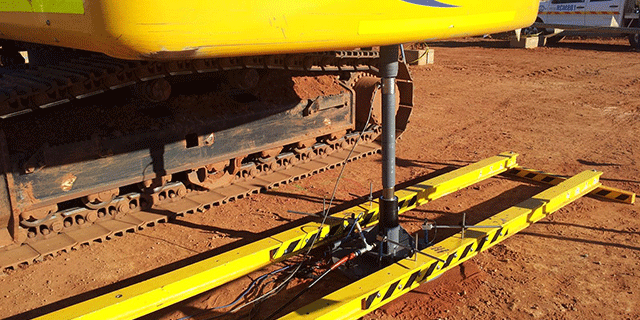

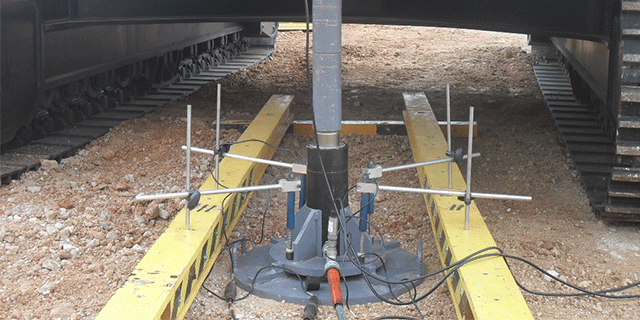

The test is performed on a prepared ground surface. If the prepared soil surface has any hollows or voids, they must be filled with dry sand or crusher dust to prepare a level surface on which to bed the plate. Our plate load test equipment is designed around a hydraulic cylinder and load cell to mobilise 250kN.

We have 3 plate sizes:

- 645mm diameter with a 765kPa max. bearing capacity

- 500mm diameter with a 1270kPa max. bearing capacity

- 300mm diameter with a 3500kPa max. bearing capacity

Displacement is measured by four 50mm travel transducers mounted to the rods in the timber beams.

Timber is used to minimise thermal distortions.

The hydraulic cylinder is controlled electronically by the data acquisition computer. This provides load ramps and holds.

The data acquisition system can log data at sample rates from 10Hz to once every 300 seconds.

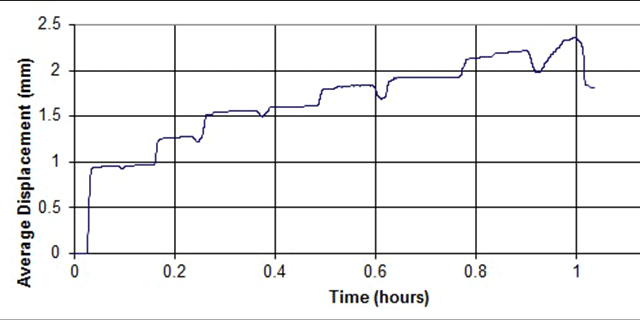

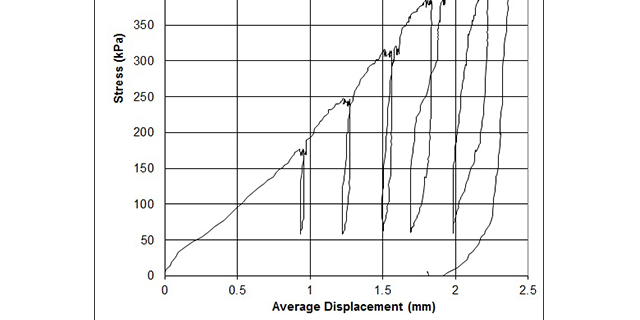

The above example plot is the soil stress against the travel recorded with the displacement transducers.

The sample rate is varied depending on what is happening during the test.

Data is presented in Excel spreadsheet format with text data and graphical plots included.

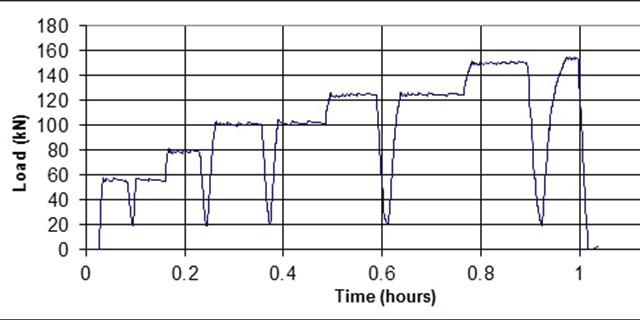

This is a plot of the load cycle applied to the plate for the stress/displacement plot to the left.