LATERAL LOAD TESTING

Lateral load testing is important for assessing the stability and performance of deep foundations, especially in regions prone to high winds, earthquakes, or other lateral forces. It helps engineers ensure that structures can withstand the lateral loads which may be encountered during their service life, thereby enhancing safety and reliability.

During a lateral load test, a horizontal force is applied to the structure at a specified height above the ground level. This force is can be applied by pulling piles together or pushing them apart.

Typically applied gradually using hydraulic jacks or other load-applying devices. Instruments such as load cells, strain gauges, or displacement transducers are used to measure the applied force and the resulting lateral displacement or deflection of the structure.

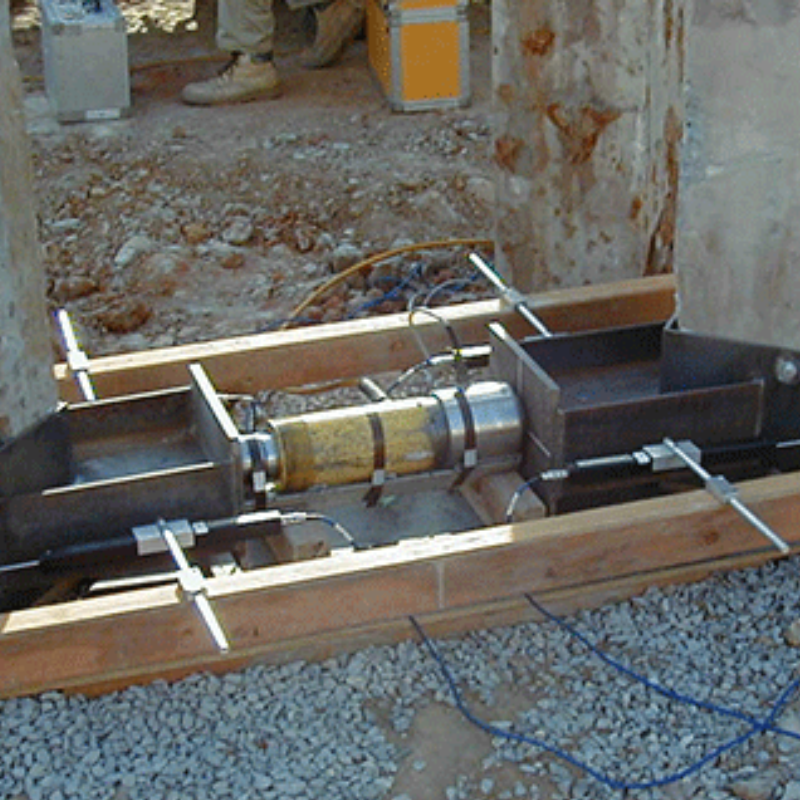

A lateral test being performed on precast piles, also with electronic data acquisition.

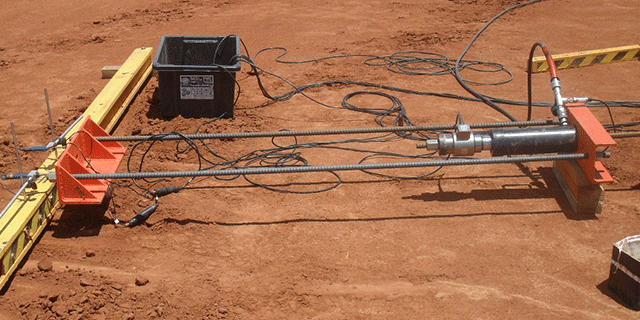

Laterally loaded screw piles using hollow cylinder and load cell arrangement with 4 displacement sensors

The test is usually conducted in multiple load cycles, with the load incrementally increased until a predetermined maximum load is reached or until a specified displacement criteria is met. The data collected during the test is then analysed to determine the lateral load capacity, stiffness, and overall behaviour of the structure under lateral loading conditions.

These screw piles are being pulled together laterally. The method uses a hollow hydraulic cylinder and load cell.