PILE TENSION TEST

Pile tension load testing enables measurement of displacement as a pile is pulled out of the ground.

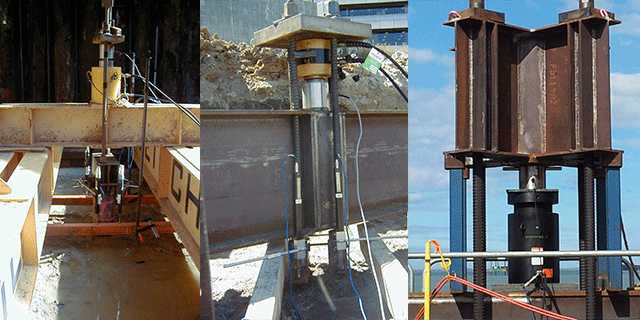

These piles are being loaded in tension using various loading configurations. Some of the piles have extensiometers and strain gauges installed down the length of the pile.

All sensors are logged electronically to a computer and provide graphical information during the test.

The procedure for undertaking a pile tension test typically involves several steps, including preparation, instrumentation, loading, and data analysis. A general outline of the process follows:

Preparation:

- Select the pile(s) to be tested based on project specifications and requirements

- Clear the area around the pile(s) to ensure safe and unobstructed access

- Install any necessary equipment, such as reaction frames or anchors, to apply and measure the tensile load

- Ensure that the pile is properly installed and secured in the ground according to design specifications

Instrumentation:

- Install instrumentation to measure parameters such as load, displacement, and strain.

- Common instruments used include load cells, displacement transducers, and strain gauges.

- Calibrate the instrumentation to ensure accurate measurement of the applied load and pile response.

Loading:

- Apply the tensile load to the pile using hydraulic jacks, winches, or other appropriate equipment

- Gradually increase the load in increments while monitoring the pile’s response as per the Client’s requirements

- Record data at regular intervals, including load applied, pile displacement as per the Client’s requirements

Data Collection:

- Continuously monitor and record data throughout the loading process

- Measure and record any settlement or movement of the pile and surrounding soil

- Ensure that data collection is performed accurately and consistently to capture relevant information

Unload and Analysis:

- After reaching the desired load level or observing specific pile behavior, gradually unload the pile

Reporting:

- Present the collected data for assessment by Engineer

Throughout the entire process, safety precautions should be strictly followed to prevent accidents or damage to equipment and personnel. This includes setting up a working area at least 20m around the testing site ensuring personel who are not actively involved in the test cannot enter the area.

Left: Tension load test on a screw pile. Center: Tension load test on a CFA pile. Right: A near shore tension test on a driven pile using a 500T load cell and hydraulic cylinder on a jack up barge.

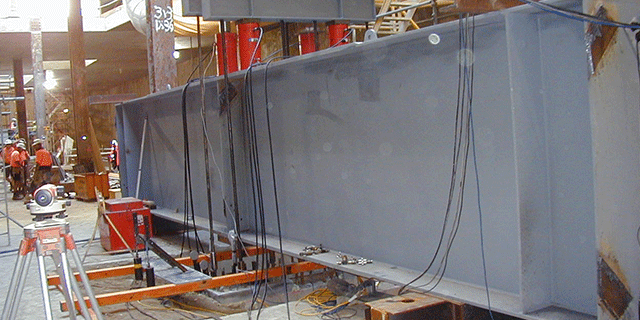

Tension test on a barrette. The barrette train gauged along its length.

Tension test on a drilled and grouted pile.